Diamond Carbide Drill Bits DE

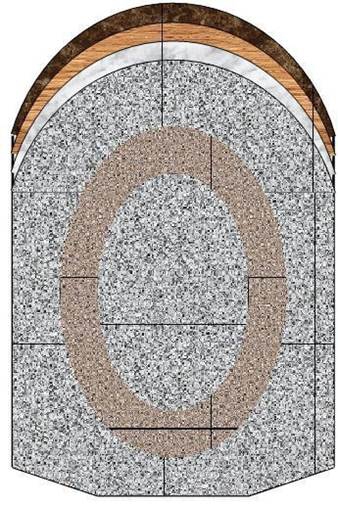

Polycrystalline diamonds

These bits are designed for deep drilling or in extremely abrasive formations where conventional bits have to be replaced repeatedly.

Advantages

- No need to sharpen pins

- Drilling on the crown is 3-5 times more

- More time for drilling and less time for tripping.

- SECURITY. Most of the injuries occur during trips, when the drill string is unscrewed and the drill pipes are changed.

- DE crowns are 3-4 times more expensive than usual ones and are made only by order.

Application practice:

Anglo Gold Ashanti - South Africa, Tau Tona mine, Carletonville

RC Underground Drilling Program February 2014

- Drilling was carried out with a RE542 pneumatic hammer with a DE bit with a diameter of 124 mm; the target length of the well was 308 meters.

- Using the DE bit, drilling was carried out without changing the bit and the target depth was reached in 4 shifts. When using a conventional crown, the same result required the replacement of 6-8 crowns and took up to 10 shifts.

Jack Hills, Western Australiaя

- DE bit buttons after 310m of drilling in ferruginous quartzite/magnetite iron ore with high silica content. The pins were not sharpened.

- Standard pins of conventional crowns under the same conditions require sharpening every 6-12 meters of drilling.

+994 515 287 203

+994 515 287 203